If you are looking for above average meter accuracy then paddlewheel flowmeters are one of your best options. They are easy to install compared to other meters and they can measure flow from either direction. If you consider the overall cost of ownership for a paddlewheel flowmeter then you will find that they are worth it. These are some of the reasons that make paddlewheel flowmeters popular.

Cost of accuracy

Every valuable item has to have a cost that guarantees its quality. Modern technology has enabled paddlewheel flowmeters to use advanced plastics and metals in their manufacturing. They have also incorporated solid state circuitry to the flowmeters and this has seen its high cost of production. However for someone who understands quality, they know that getting this product is a long term investment that will last and guarantee performance.

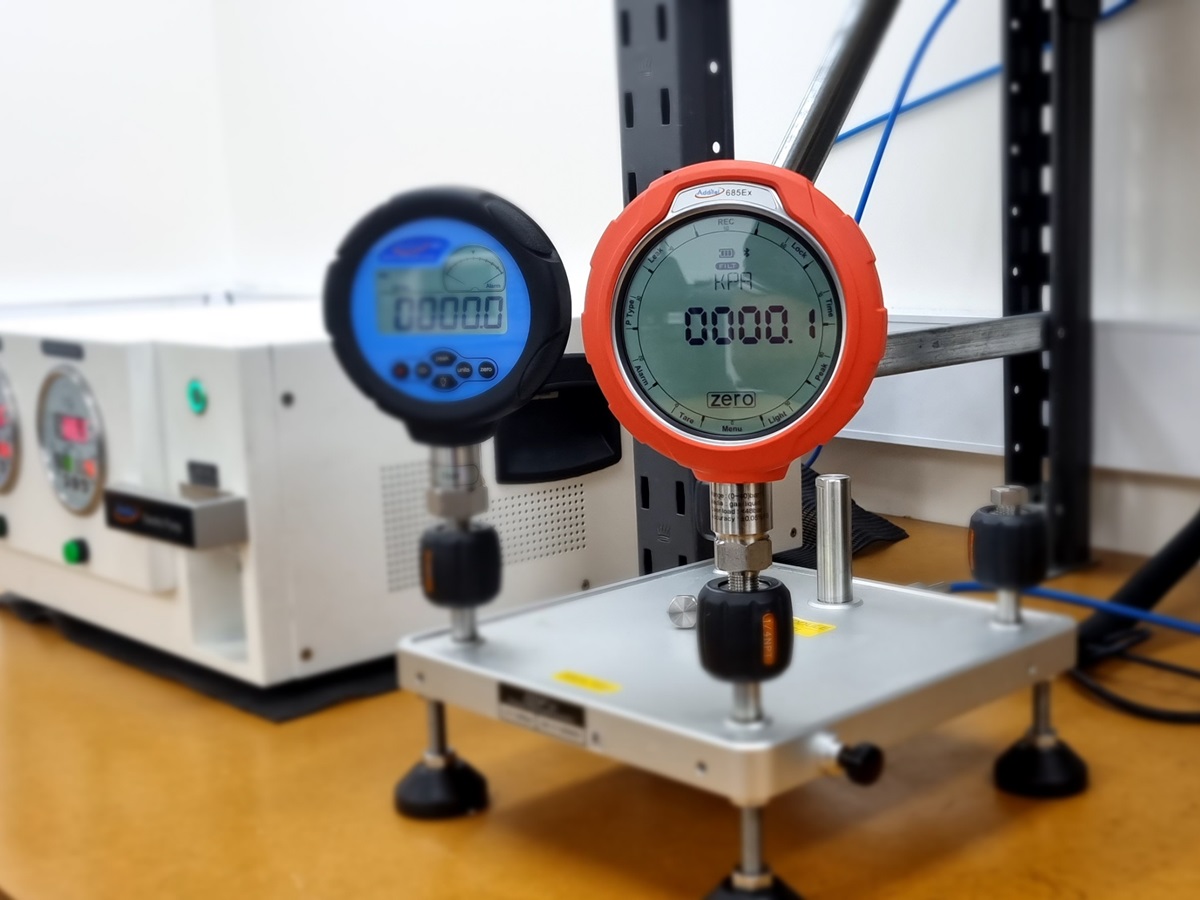

Paddlewheel flowmeters have their paddle sensors tested and their accuracy confirmed. They use facilities that are computer-enabled that test the paddle sensors. In other flowmeters installations, variables can sometimes affect the meters ultimate performance.

Easy to install

Paddlewheel flowmeters can be used to measure from any direction because they can be installed either vertically or horizontally without affecting the overall performance of the meter. They come complete with a digital display, a sensor and a pipe fitting. They can easily be installed into a piping system. For larger pipe sizes it is convenient to get the meters that come with saddle mount pipe fittings.

Battery operated

Paddlewheel flowmeters have advanced over the years and now they do not need to be connected to electricity for them to operate. They use an advanced solid state circuitry which uses the common battery to operate. These batteries can go up to one year and they can be easily replaced without disrupting the meter or even interfere with the factory settings. Other flow meters require electricity to operate and in case of electricity disconnections, these can cause interruptions. The paddlewheel flowmeter ensures productivity throughout.

Maximized performance

To get the best performance from your paddlewheel flowmeter ensure that you avoid using it to measure dirty fluid with rocks and particles to avoid damage to the axle or paddle. Ensure that you follow the set installations recommendations for the straight length pipes. Just like any other device, be sure to follow these instructions to the letter otherwise you will not be guaranteed optimum performance.

Paddlewheel flowmeter maintenance

The paddle and axle in the meter are usually in direct contact with fluids. The paddle spins at a speed that is proportional to the flow rate. With time, these components wear out and need to be replaced. Compared to other flowmeters, the paddlewheel may seem to be at a disadvantage because of this. But put in mind that meters that are operated on the high end of calibration tend to wear more that those operated at low ends. So that means if neglected a paddlewheel flowmeter will give inaccurate readings. This feature ensures that paddlewheel is always performing at its optimum so reality you end saving more on your overall maintenance costs.